You may be starting out smaller, but you can see a path that gets you where you want to be some day.

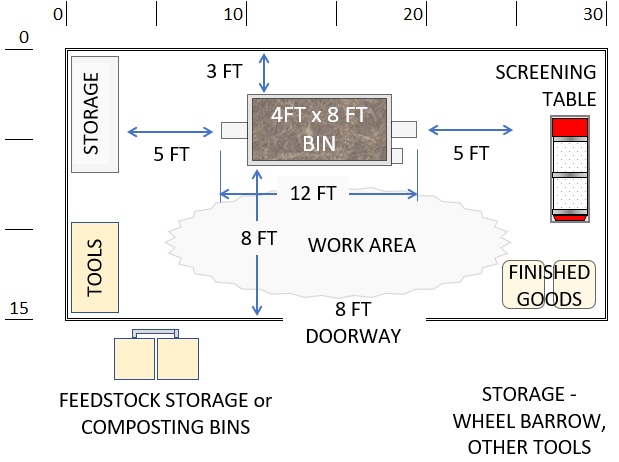

Here’s a sample layout for a small 15 x 30 ft (5 x 10 m) worm composting shop. This workspace has areas for tools, screening, storage, and a central work area. The CFT, the doorway, and the task areas are all arranged for easy access. There is ample space to maneuver. It could be 25 ft wide and still work well, or a second module could be added. Don’t underestimate the room you’ll need for maneuvering wheelbarrows and long-handled tools. Or larger pieces like a screener that you might need to roll in and out. And you’ll want a space to store feedstock and your finished product.

Not everyone has a luxury of space. You can make it work in a shipping container, but it’s tight quarters!

The best floor for your vermicast workspace is concrete or similar solid material. Cement footers can work well for unpaved floors. You’ll need room to work around your CFT and other equipment. Space on the side for feeding, watering and harvesting, and access at the ends for the winch or motor controls.

Areas to Consider for Space Planning:

- Pre-composting area

- Feedstock loading areas

- Vermicomposters lines

- Screening area

- Bagging & weighing area

- Material handling areas

- Conveyance & automation systems

- Inventory storage: raw and finished goods

- Shipping/receiving area

- Equipment service area

- Quality assurance & analysis

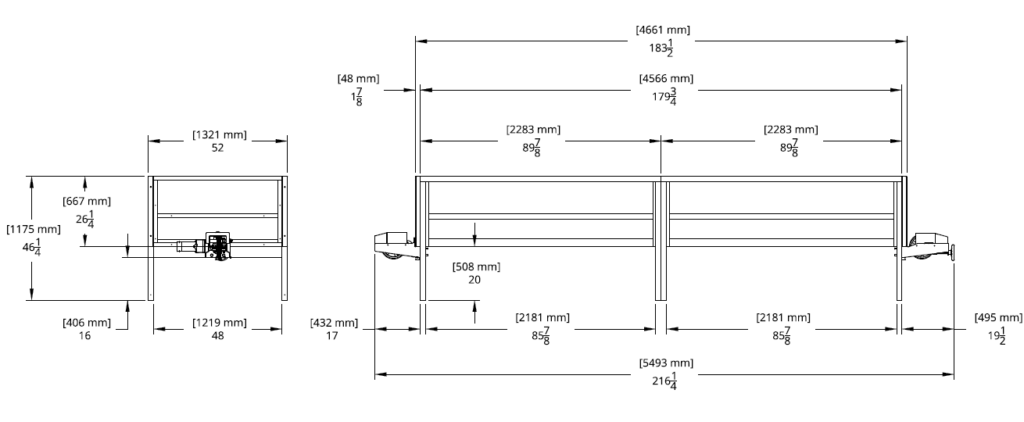

Start with the dimensions of the CFT itself. Shown here is a 2-module setup, but you can use it to estimate dimensions for a single module or multiple modules.

For the working aisle, allow for 7 ft (2 m) or more from the CFT wall to an outer wall or other barriers. At each end, leave yourself 5 ft (1.5m) to operate the winches or motor drive. Along the back side of the bin, 3 ft (1 m) is sufficient for occasional access to sweep any out-of-reach vermicompost or to reach into the bin from the back side. So for a 2-module line shown above, an ideal space would be:

Room Length

18 ft – length, 2-modules

10 ft – 5ft at each end

28 ft long

Room Width

4 ft – CFT width

7 ft – working aisle

3 ft back clearance

14 ft wide

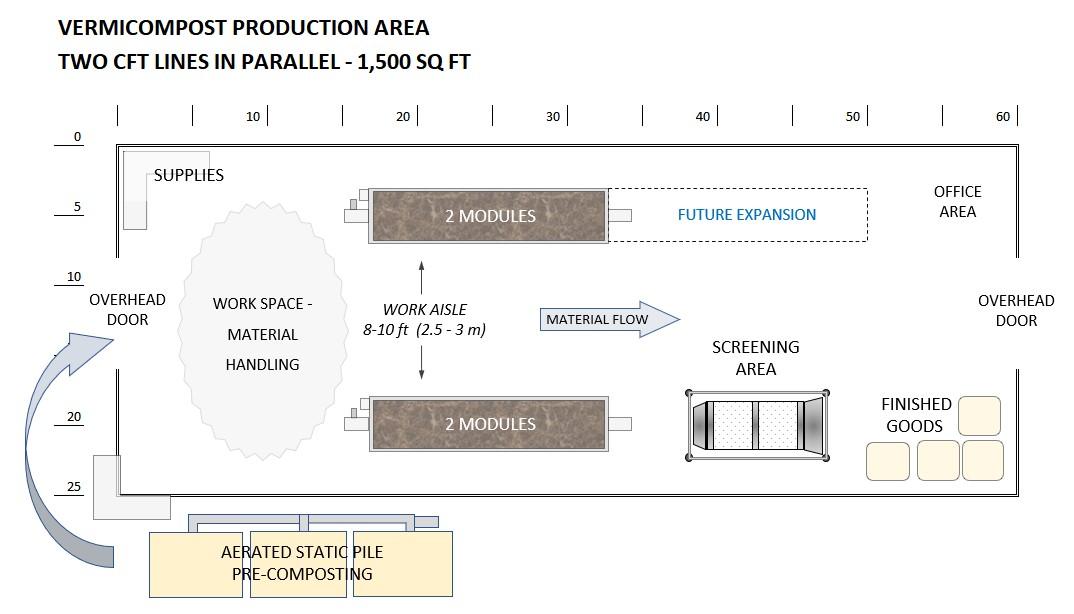

With multiple lines it is efficient to arrange lines in pairs side by side, sharing a common work aisle.

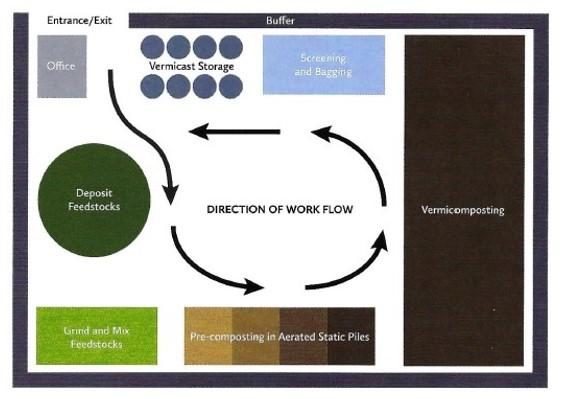

Another important concept to keep in mind is material flow – the direction of in-process goods through and around your space. It is always a good idea to avoid raw and finished goods from crossing paths.

Here is a chart showing the idea of material moving unimpeded through your workspace.

Now, we can translate this into a floor plan and give ourselves room to grow, and we might come up with something like this: