The Business End of Vermicomposting

Many people are familiar with vermiculture – the life-science side of things – but the amounts to feed and harvest, the timing, weights and measures, these are not well documented.

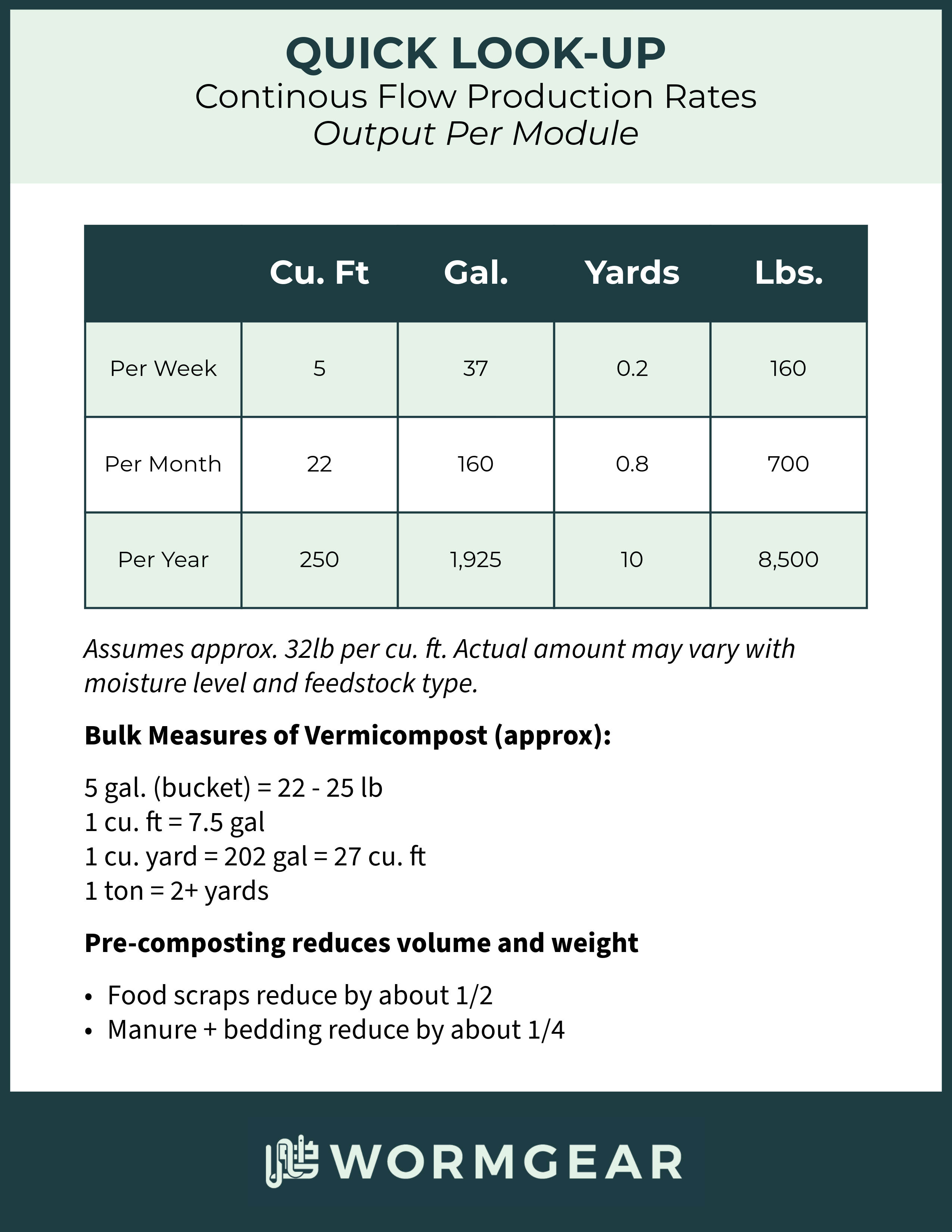

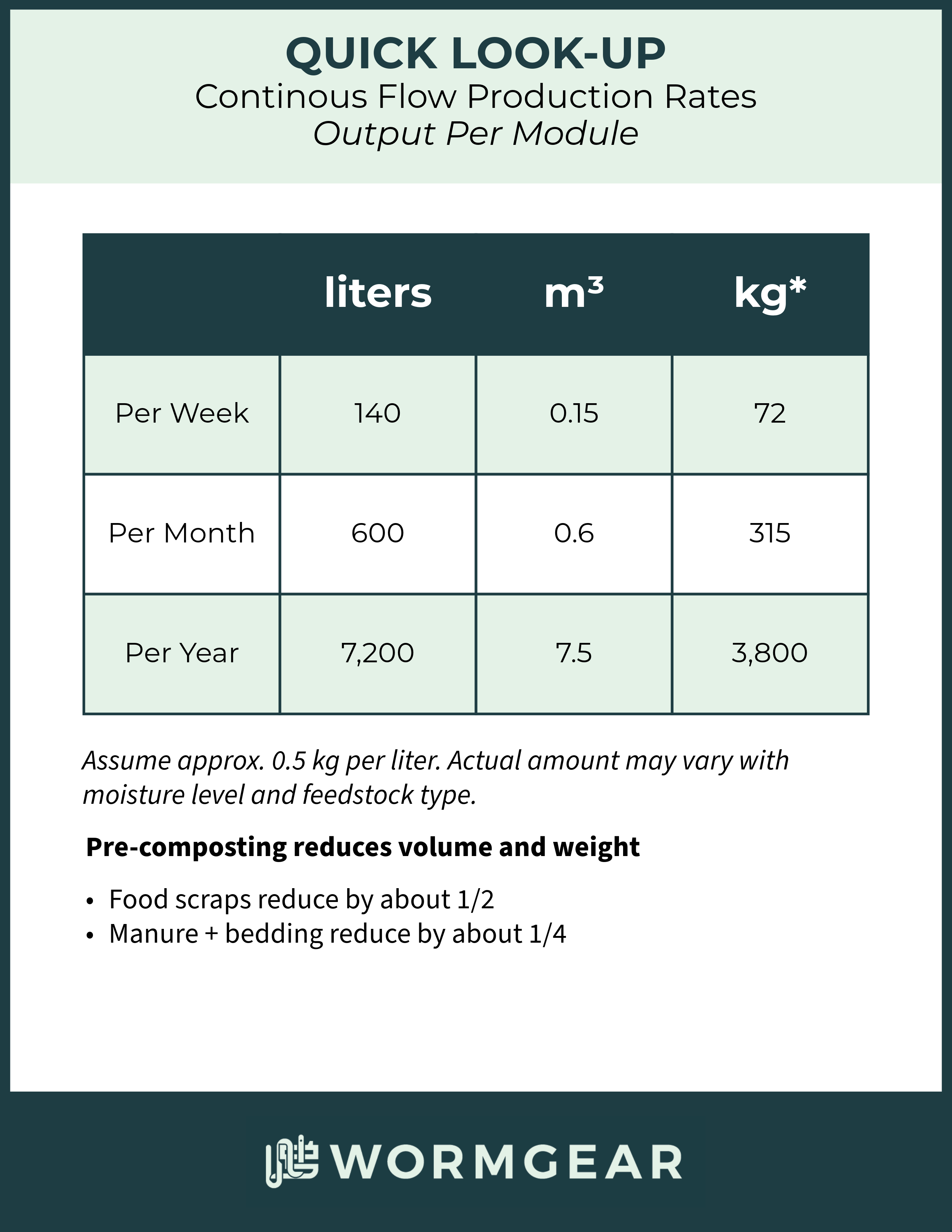

Here are many of the important rates and assumptions you will use when running your CFT system, or just thinking about it:

Key Dimensions

For starters, our first key dimension is surface area at the top of the bin. This is because composting worms stay near the surface, so their population density can be defined in terms of weight per square feet or meters. Each one of our CFT

modules are 8′ x 4′, or 32 square feet of surface area.

Our second key dimension is the working depth in the bin, which should be about 20-22″. We fill the bin in layers that are a few inches or centimeters thick, and we harvest from the bottom in similarly-sized layers.

These two key dimensions figure into nearly everything else we need to know. We can round off some of the figures to make them easier to remember and work with.

Worm Population

We recommend starting with a minimum worm population of 1/2 lb per sq.ft. – more if you can. For our CFT modules, that means 16 lbs. minimum to start. The herd will increase in population until they reach 1-1/2 to 2 lb. per sq.ft., where they level off at their most productive density.

Harvesting

When starting up a new CFT, you fill it layer by layer, one week at a time, allowing the worms to digest the new feedstock. Meanwhile, the castings from each previous layer continue to process and mature from microbial activity. So, it takes about 16 weeks to fill the CFT, and by that time the stuff that’s been there the longest at the bottom of the bin is ready to harvest.

You will run the cutting bar once per week, round trip across and back. It releases about 1 inch of vermicompost each way, or about 2 inches harvested per week.

Assuming you screen your harvested product, some of each batch will be in chunks that are too big or not fully digested, and this goes back in the bin for another trip through. Also, you’ll let your fresh harvest air dry for a couple of days, and it loses some weight and shrinks a bit. Combined, your finished product will be reduced to about 3/4 of its original amount.

Production and Feedstock

Based on that, each 8-ft module will yield about 3-1/2 cubic feet, or 25 gallons, of finished product. (There are 7-1/2 gals per cu.ft.). By weight, this is about 125 lb. per week. (There are 36 lb. per cu.ft.)

Wholesale quantities of vermicompost are sold by the ‘yard’, like mulch or other landscaping materials. There are 27 cubic feet in a yard, so it will take 7-8 weekly harvests to get a yard. Or thinking of it another way, 4 modules would produce a full yard every 2 weeks.

We also need to know how much fresh feedstock we’ll add to the bin each week. Feedstock shrinks in volume as it gets processed by worms and microbes. Experience shows that it will reduce by about half from start to finish. Since we are harvesting about 2 inches from the bottom each week, we’ll add 3-4 inches of feedstock to the top each week. That amounts to about 1/4 yard of feedstock material per each module.

Income Potential

Now that you know how to calculate output, you can get a better idea how large a system you need. If you are selling your VC, you can make a good estimate of your income potential. If you are processing a regular amount of waste material like manure, vegetation or yard waste, you can see how much CFT capacity you need.

If it is a business investment, you will be looking for your breakeven – the time it takes for the investment to pay for itself. For a single CFT module, that works out to be about 18 months after initial startup and decreases with more modules. Most companies like to see a payback in 24 months or less.

And business or not, we benefit from knowing we are contributing to sustainability.